Medical Devices Optoelectronic Sensors in Medical Applications

Electronic components have been incorporated into medical equipment designs for years. Until recently, medical electronics has been focused primarily on the institutional side of the medical market, in expensive diagnostic equipment, such as MRI and CAT scanning machinery for use in hospitals and clinics. An aging and expanding population is accelerating the development of new and different medical equipment. Professionals in health-care settings want real-time, reliable, and accurate diagnostic results provided by devices that can go to the patient, whether he or she is in a hospital or clinic or at home, being monitored remotely. The equipment should be appropriate for both home care and ambulatory treatment; it must be patient friendly, both technically and physically; and it must be small, light, and energy efficient.

Electronics-based medical equipment requires sensors to convert the various types of stimuli (optical, mechanical, etc.) into electrical form. Many different types of sensors have been included in medical equipment designs. Sensors in current and future medical equipment need to be highly reliable, small, packaged with surface-mount technology (for a smaller footprint on the PCB and for ease of manufacture), low cost, highly accurate, and have no lead content. This article will address why optoelectronic sensors work particularly well in the medical equipment environment, in both institutional and home-care equipment designs.

Optoelectronic Sensor Basics

By definition, an optoelectronic sensor is a device that produces an electrical signal proportional to the amount of light incident on its active area. A number of devices meet this definition, but none is more prevalent than the semiconductor photodiode. Over the years, this two-terminal device has become the mainstay for light sensing.

Designers today—especially medical equipment designers—are now asking for more than just a light-to-current transducer. They are looking for more functionality integrated around this semiconductor workhorse, to provide themselves with improved performance and reliability, and lower system cost in the highly cost-sensitive medical equipment market. Added integrated functionality also removes the need for certain subsystem circuit designs and thus helps shorten the design cycle.

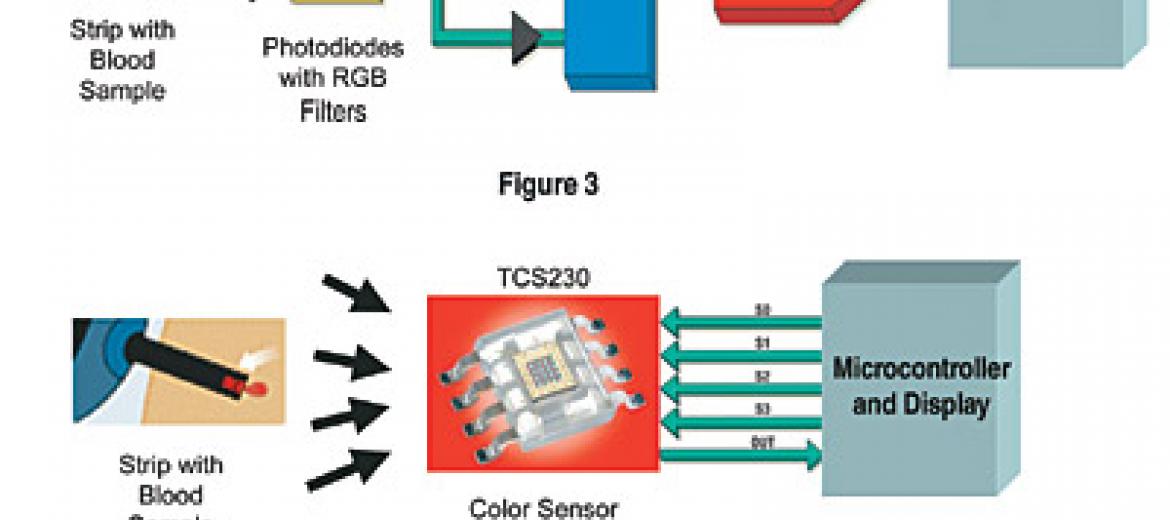

Integrated optoelectronic sensors are designed to respond to light so that they can recognize things such as patterns, images, motion, intensity, and color. The sensor's ability to perform this recognition (and the complexity of the recognition possible) depends upon the type of integrated optoelectronic sensor.

All of these types of sensors can be, and are, used in medical equipment applications. They help eliminate human error while providing more accurate readings and faster results. Rather than rely on human judgment to match colors or identify changes in light intensity, the sensors are designed to read or measure light— a real-world signal considered to be very stable and highly accurate—in a reliable, repeatable way. Data from the optoelectronic measurements are fed directly into the computer system, removing another possible source of error. The sensors are noncontact, able to perform their sensing or measurement functions without the need for physical contact with specimens such as blood, urine, or other bodily fluids. This is critical because if the specimens are tainted in any way, the resulting readings and measurements may not be accurate.